Product Details

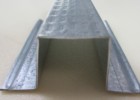

Ceiling Battens

Ceiling and roof battens direct screw or clip fixed battens are designed as a direct replacement for timber battens for both internal ceiling and wall linings as well as light weight steel roofing and wall cladding systems. At 600mm spacing’s it c...

Product Description

Ceiling and roof battens direct screw or clip fixed battens are designed as a direct replacement for timber battens for both internal ceiling and wall linings as well as light weight steel roofing and wall cladding systems.

At 600mm spacing’s it can span up to 1200mm in both internal and external applications.

It is available in 0.55mm G250 Z275 and 0.75mm G550 Z275, lengths are available from stock or you can choose to have them run cut to length to reduce waste on site.

Also available are the PC30-30mm perimeter channel in stock 3m lengths and the ED40-40mm Easy Dwang angle in stock 3m lengths.

DURABILITY

All products are Z275 Galv coated backed by the manufacturers 50 year durability statement.

Ceiling and Roof Battens are manufactured from hot dipped galvanised steel with a coating weight of 275gram/sqm, in line with other common lightweight steel structural building products.

This gives good protection in most exposed internal environments, and for external use in moderate marine environments. Where used in a lined interior dwelling, a thermal break should be installed between the Ceiling and Roof Battens and the cladding to avoid thermal bridging. Where sections are exposed to salt spray but not rain washing, maintenance is required to remove any build up of salt deposits on the surface.

Run off from, or contact with, materials which are incompatible with zinc should be avoided.

HANDLING AND STORAGE

Ceiling and Roof Battens must be kept dry during storage as water present between close stacked sections will cause premature corrosion. If they become wet they should be separated and stacked openly to allow for ventilation to dry the surface.

LENGTHS

Ceiling and Roof Battens are available in long run lengths up to 12 metres, depending on the available transport and handling facilities. Stock lengths may be available from your local stockist.

CUTTING

Cutting is preferably done by shear or hacksaw. When using abrasive disc blades care must be taken to ensure the swarf produced does not affect other materials and the burred edge should be cleaned off at the completion of cutting